Tag Archive: Roundness

Roundness, Sphericity and Microproppants

Gravel, sand, and other aggregates must be separated and classified based on their sphericity and roundness to determine the suitability for various applications. These two terms describe the shape of these materials in two different dimensions.

- Sphericity measures how close the rock is to a perfect sphere.

- Roundness is a measurement of the edge of the rock.

These measurements provide a means of documenting the difference between various shapes, such as rhombus and a football, or a circle and an octagon. The mathematical equations for determining roundness and sphericity can be found here.

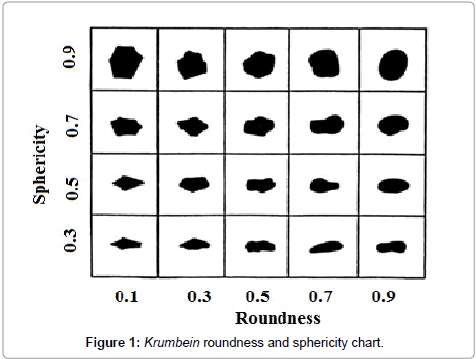

The Krumbein Roundness and Sphericity Chart

Most applications for aggregate don’t require the level of accuracy provided by the above mathematical calculations, so a simple visual test is easier and faster. The Krumbein Roundness and Sphericity Chart has been widely adopted as a visual method for determining the shape of an aggregate. This chart can be seen in Figure 1.

Applications in the Oil and Gas Industry

Measuring sphericity and roundness is critical for fracking operations in the oil and gas sector, as these properties determine the strength and permeability of the aggregate. Silica sand’s ability to withstand high compression stresses depends on both of these factors. If the sand is on the low end of the sphericity and roundness chart, the particles will have too many sharp edges.

When compressive forces are applied directly to those edges, the stress concentrations increase exponentially. If the sand is under too much stress, it will shatter, further increasing the amount of jagged-edged particles. This process can have a domino effect until nothing remains but a vein of silica dust deep in the ground.

Silica sand serves two purposes in fracking:

- It acts as a proppant, which props open the cracks in the shale.

- It allows oil to flow back to the well head.

Fracking sand must remain permeable or it has the opposite of its intended effect. Without gaps between the grains of sand, oil cannot flow between the particles. If the silica turns to dust, it instead blocks the flow of oil.

Microproppants

Sand particles smaller than U.S. Sieve size 140 mesh are referred to as microproppants. There are smaller silica products known as silica flour, but these flours are ground into dust and rate very low on the sphericity and roundness chart. Silica flour is too jagged and has very low crush strength.

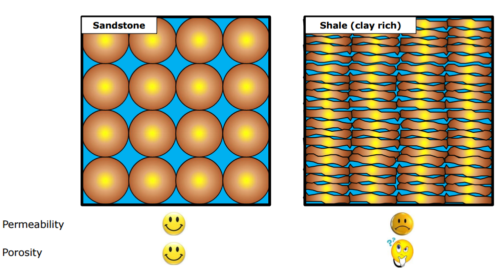

As a visual reference, imagine stacking basketballs. The rounded edges of the balls provide space for fluid to flow between each ball. Silica flour is more like stacking Legos. There is no space to allow oil to flow back into the well head between each “Lego.” See Figure 2.

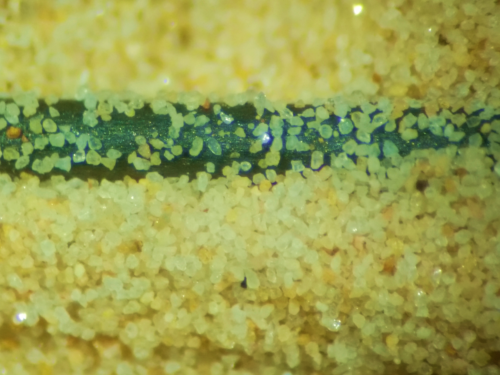

For fracking, it’s important to source silica sand that is still whole-grain rather than ground or crushed, ensuring that oil will still be able to flow between the grains. Figure 3 below is a photo of 200-grain mesh whole-grain silica sand. The dark column is a 0.7 mm pencil lead as a size reference.

These whole-grain microproppants rank much higher on the sphericity and roundness chart, and thus feature a higher crush resistance than ground silica flours. This ultimately adds to the productivity and service life of the well.

Silica Products From MS Industries

MS Industries provides high-quality whole-grain silica products for use in oil and gas applications. Our silica sand features consistent size, color, chemistry, ensuring reliable well performance with an optimal service life. For more information about our silica sand products, please contact us or request a quote.